Customized Handling Cylindric Objects Railway Transport Car

Customized Handling Cylindric Objects Railway Transport Car,

Heavy Load Transfer Car, material transport trolley, v-frame handling car,

Advantage

Electric trackless transfer carts have many advantages:

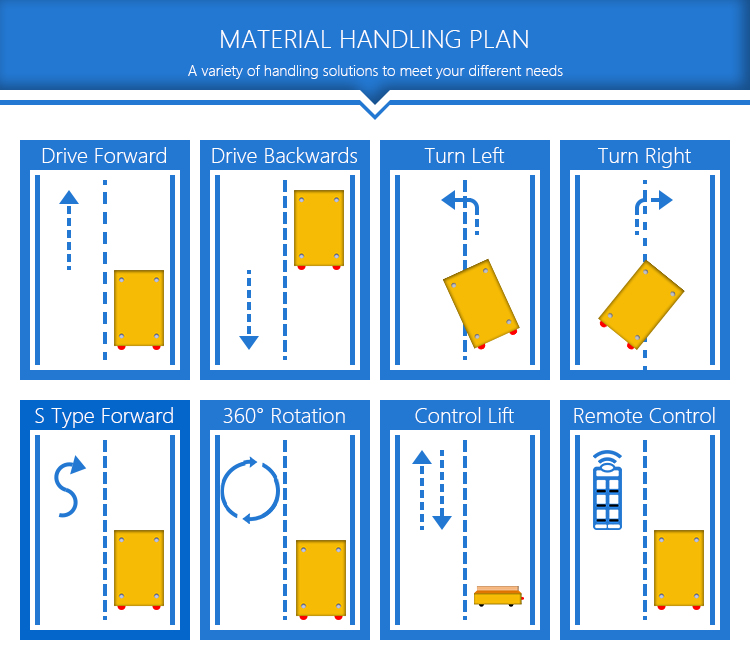

1.Not only does it operate without restrictions, but it can also turn 360° in place to adapt to a narrower space.

2.The use of imported polyurethane wheels can ensure that the ground is not damaged.

3.Functions such as 360-degree protection without dead ends and automatic stop in case of people ensure safety issues during the operation of the electric trackless transfer cart.

4.The operation design is more user-friendly, and you can use the handle, remote control, touch screen, and joystick operation methods.

Application

Application areas: metallurgy and mining, shipbuilding, mold stamping, cement plants, steel deployment, transportation and assembly of large machinery and equipment, etc.

They have the characteristics of high performance, low noise, no pollution, flexible operation, safety and convenience.

Technical Parameter

| Technical Parameter of BWP Series Trackless Transfer Cart | ||||||||||

| Model | BWP-2T | BWP-5T | BWP-10T | BWP-20T | BWP-30T | BWP-40T | BWP-50T | BWP-70T | BWP-100 | |

| Rated Load(T) | 2 | 5 | 10 | 20 | 30 | 40 | 50 | 70 | 100 | |

| Table Size | Length(L) | 2000 | 2200 | 2300 | 2400 | 3500 | 5000 | 5500 | 6000 | 6600 |

| Width(W) | 1500 | 2000 | 2000 | 2200 | 2200 | 2500 | 2600 | 2600 | 3000 | |

| Heigth(H) | 450 | 500 | 550 | 600 | 700 | 800 | 800 | 900 | 1200 | |

| Wheel Base(mm) | 1080 | 1650 | 1650 | 1650 | 1650 | 2000 | 2000 | 1850 | 2000 | |

| Axle Base(mm) | 1380 | 1680 | 1700 | 1850 | 2700 | 3600 | 2850 | 3500 | 4000 | |

| Wheel Dia.(mm) | Φ250 | Φ300 | Φ350 | Φ400 | Φ450 | Φ500 | Φ600 | Φ600 | Φ600 | |

| Wheel Quantity(pcs) | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 6 | 8 | |

| Ground Clearance(mm) | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 75 | 75 | |

| Running Speed(mm) | 0-25 | 0-25 | 0-25 | 0-20 | 0-20 | 0-20 | 0-20 | 0-20 | 0-18 | |

| Motor Power(KW) | 2*1.2 | 2*1.5 | 2*2.2 | 2*4.5 | 2*5.5 | 2*6.3 | 2*7.5 | 2*12 | 40 | |

| Batter Capacity(Ah) | 250 | 180 | 250 | 400 | 450 | 440 | 500 | 600 | 1000 | |

| Battery Voltage(V) | 24 | 48 | 48 | 48 | 48 | 72 | 72 | 72 | 72 | |

| Running Time When Full Load | 2.5 | 2.88 | 2.8 | 2.2 | 2 | 2.6 | 2.5 | 1.8 | 1.9 | |

| Running Distance for One Charge(KM) | 3 | 3.5 | 3.4 | 2.7 | 2.4 | 3.2 | 3 | 2.2 | 2.3 | |

| Max Wheel load(KN) | 14.4 | 25.8 | 42.6 | 77.7 | 110.4 | 142.8 | 174 | 152 | 190 | |

| Reference Wight(T) | 2.3 | 3.6 | 4.2 | 5.9 | 6.8 | 7.6 | 8 | 12.8 | 26.8 | |

| All trackless transfer carts can be customized, free design drawings. | ||||||||||

Handling methods

Handling methods

Material Handling Equipment Designer

BEFANBY have involved in this field since 1953

+

YEARS WARRANTY

+

PATENTS

+

EXPORTED COUNTRIES

+

SETS OUTPUT PER YEAR

LET’S START TALKING ABOUT YOUR PROJECT

Material handling vehicles are a type of transportation equipment widely used in industrial production lines. They are easy to operate and highly efficient, and can improve the efficiency and production efficiency of production line operations. The design and manufacture of modern material handling vehicles pay more attention to innovation and practicality, and are usually equipped with track laying and secondly with coiling devices. The body of the vehicle can be adjusted and disassembled according to requirements to increase the size of the table. This flexible and adjustable design can greatly improve the convenience of material handling.

No need to lay tracks, which not only saves time, but also reduces unnecessary manual operations and transportation costs. The coiling device on the vehicle body is a very practical lifting device, especially suitable for handling heavy objects. The use of coiling devices can make unloading more convenient and quick. At the same time, the disassembly function of the material handling vehicle can also freely adjust the size of the vehicle body frame to meet different handling needs.

In general, the material handling vehicle is an efficient, practical and safe handling equipment. It makes full use of modern technology and technology to improve the efficiency and benefits of industrial production. We hope that this equipment can be more widely used and make greater contributions to the process of industrial modernization.